If there are regulatory or special requirements for your job, process or product know and be able regrowth them (i.e. FDA, FAA, special handling requirements; soldering; sterilization).

Safety may be the major factor when buying the diving gadgets. Before purchasing truly see the NFPA, ISO 9001 certification consultants 9001 standards. In the time of purchasing the system you should ask for your compliancy documents that could be the guaranty in the system’s air quality, containment and air monitoring. Perform confirm good quality of of it by seeing the resources by which a system is built.

In my consulting practice I have observed people in levels in organization getting “uptight” or having “audit anxiety” about an ISO registration or continuing effectiveness (surveillance) audit by their registrar. Proper preparation can help lower the anxiety location. These tips can help you and everybody in business be better prepared for the audit.

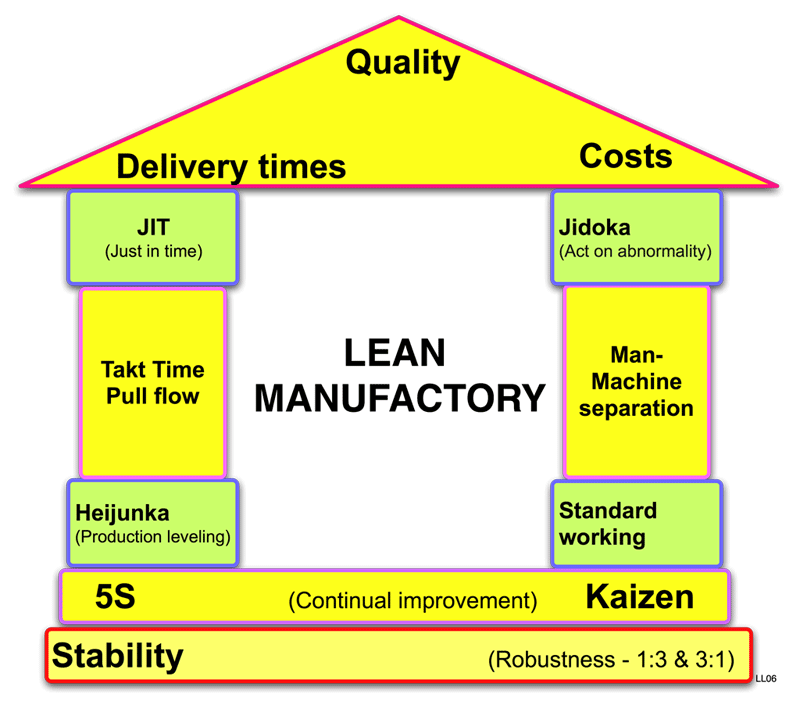

At Toyota facilities at the globe, “kaizen” is a thing mentioned recurrently. The word means “continuous improvement” and can be a key aspect in Toyota class. Kaizen has been incorporated in the ISO 9001 certification consultants driving our engineering and manufacturing teams to constantly improve our lift trucks. Furthermore, it drives our service colleagues.

Companies spend millions of dollars each year developing mission and vision statements, identifying their brand, and then communicating their brand promise through various media. Employees are the primary “media” their majority of brand contacts. In most companies, employees don’t learn the brand promise well enough to communicate it, inconvenience if the live it and articulate it clearly.

The implementation of the six sigma process dates for you to 1985 when Motorola adapted this technique to improve their production operation. It became most liked after General electric started applying it in the majority 1995. Normally, this process is utilized for those manufacturing processes that need a significant improvement as production steps. In the later period this particular method was adapted by a lot of organisations going without shoes was introduced as a part of the curriculum in many business educational institutions.

Mass production focused on economies of scale; TPS focuses on economies of flexibility. Mass production focuses on results, TPS focuses on process. Push systems concentrate on a schedule; pull systems focus on consumption.