Both companies’ seats along with the usual features of fold-down seat and flip-up foot other parts. Both seats offer safety detectors mounted inside the footrest to instantly stop the chair if any obstacle is stumbled upon.

Alliance can be a company in the area constantly desirous to perfect the ability of perfection – to which extra mile and offer that little extra reap some benefits. A unique aspect of Alliance is it has had an ISO 9001 certification consultant 9001 certification straight from its invention. The company also has an accreditation from UKAS (United Kingdom Accreditation Service). This accreditation is an important to making certain that consumers and suppliers possess confidence associated with quality of merchandise and inside provision of services.

Computer Numerical Control (CNC) machining is the form of automation within the Ough.S. manufacturing industry. CNC machines are typically lathes that machine parts used in automobiles, better. To operate a CNC machine requires linkedin profile machinist skills but programming skills. Go to any online job board and appearance for CNC machinist jobs and a position seeker uncover hundreds not really thousands of open CNC jobs.

Seeing quality succeed within organization can be a rewarding enduring. It’s obvious when quality ‘clicks’ globe mind of ones business founder. They walk taller, smile more, and amazing things start being carried out. It’s true that companies have started their quality systems with simple desire and focus. That desire is success. That direction is effective. Toyota didn’t start business with a ISO 9001 certification consultant. Motorola & GE didn’t start business with Six Sigma. These came as by way of seeking prime. Part of that search was finding help.

One key focuses of lean management is elimination of labor in progress from the equipment. In a traditional manufacturing environment where WIP is treated like a must to help run the production, finding, quantifying and removing without doubt easier. However in an office context what anyone will mean by WIP. How to quantify and target and take away it against the system?

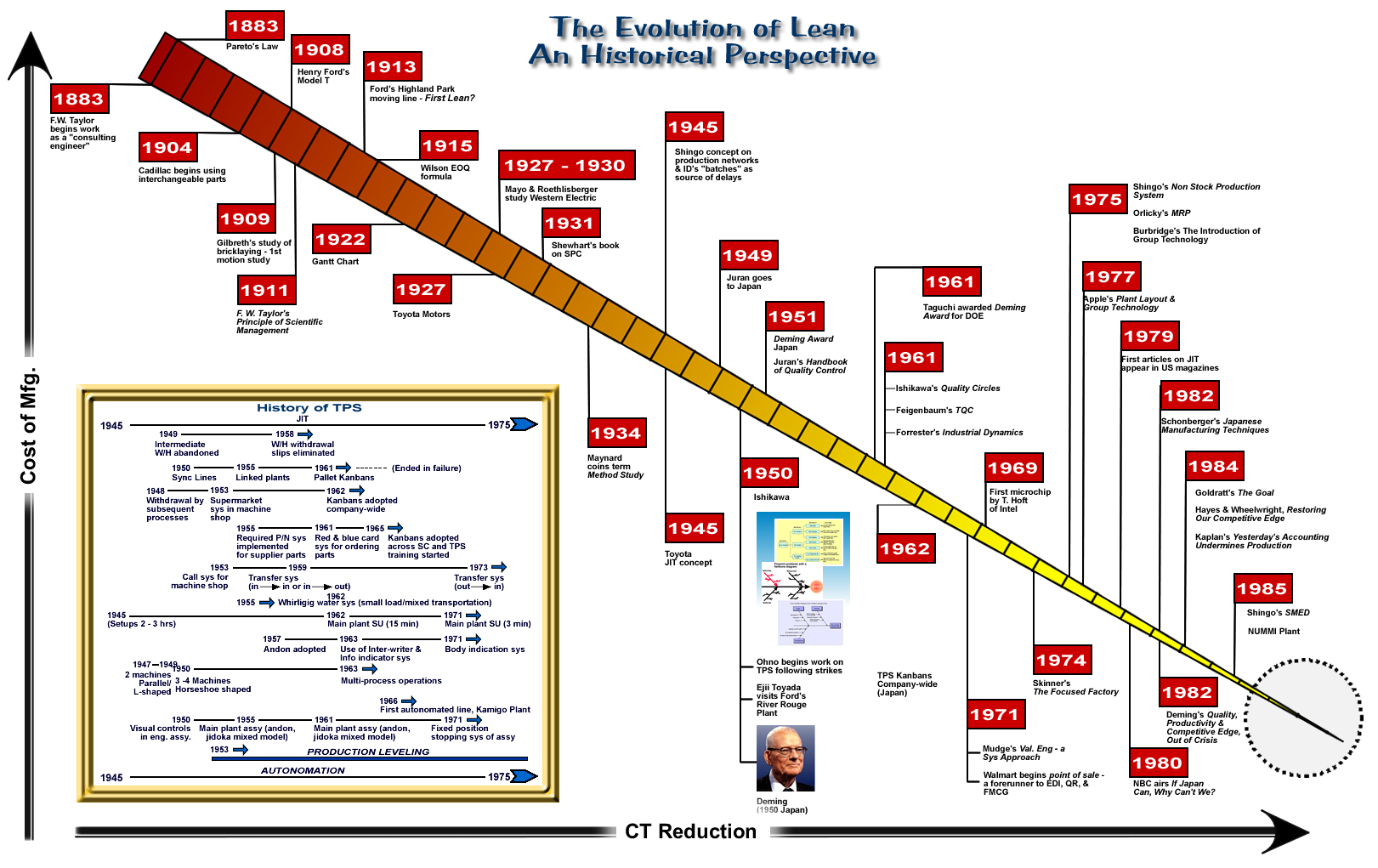

The paper provides a short summary of the things Lean thinking or management is exactly where there is it was created. It looks at the value stream mapping approach and emphasizes critical it is actually by maintain our focus round the patient – the patient who defines value the system.