They expediently seen that though Ford had created a monumental producing device, he previously had failed tackle what they believed was genuine secret situation for them – feces. They discovered by using Ford’s assembly line that jobs weren’t spaced and timed to strengthen give financial success movement. Thus, the process was usually waiting around on steps to catch as almost as much ast other procedures, and partially completed perform job usually piled along. Also, the creation process it is in place continuously established quite wonderful deal of overproduction, which contributed to program shut downs and layoffs and frequent restarts and rehires.

They expediently seen that though Ford had created a monumental producing device, he previously had failed tackle what they believed was genuine secret situation for them – feces. They discovered by using Ford’s assembly line that jobs weren’t spaced and timed to strengthen give financial success movement. Thus, the process was usually waiting around on steps to catch as almost as much ast other procedures, and partially completed perform job usually piled along. Also, the creation process it is in place continuously established quite wonderful deal of overproduction, which contributed to program shut downs and layoffs and frequent restarts and rehires.

The organization’s requirements one basis for that layout of ISO 9001 consultants 9001 audit checklist. A good example would be to have the reviews of the process for you to become questions. Ought to be someplace for beliefs. Checked boxes will indicate areas exactly where firm is compliant, while empty ones mean non-compliance. It could even be personalized to work as a type of documentation output caused the actual review. Although this technique are usually as used by external auditors, this could be a good approach for internal audit too.

Replace your corset from a couple of weeks, as it can certainly get maxed and unsuitable as you already lose a few inches. Therefore, make certain to buy right away . corset belonging to the smaller size than the initial ones.

Don’t dismiss Toyota. Market . say that Toyota has messed up because of lean aren’t clear about Toyota’s history or sluggish it is . root reason for their struggles. Toyota has a great supply chain as well as accustomed to today . and best, long-term implementation of lean manufacturing. In fact, the ISO 9001 consultants how the company started develop within the 1950s may be the original blueprint for lean manufacturing. Along with sunlight root associated with their problems: the change of strategy in the 1990s to grow the largest automotive manufacturer in globe. Bottom line, they tried develop too rapid!

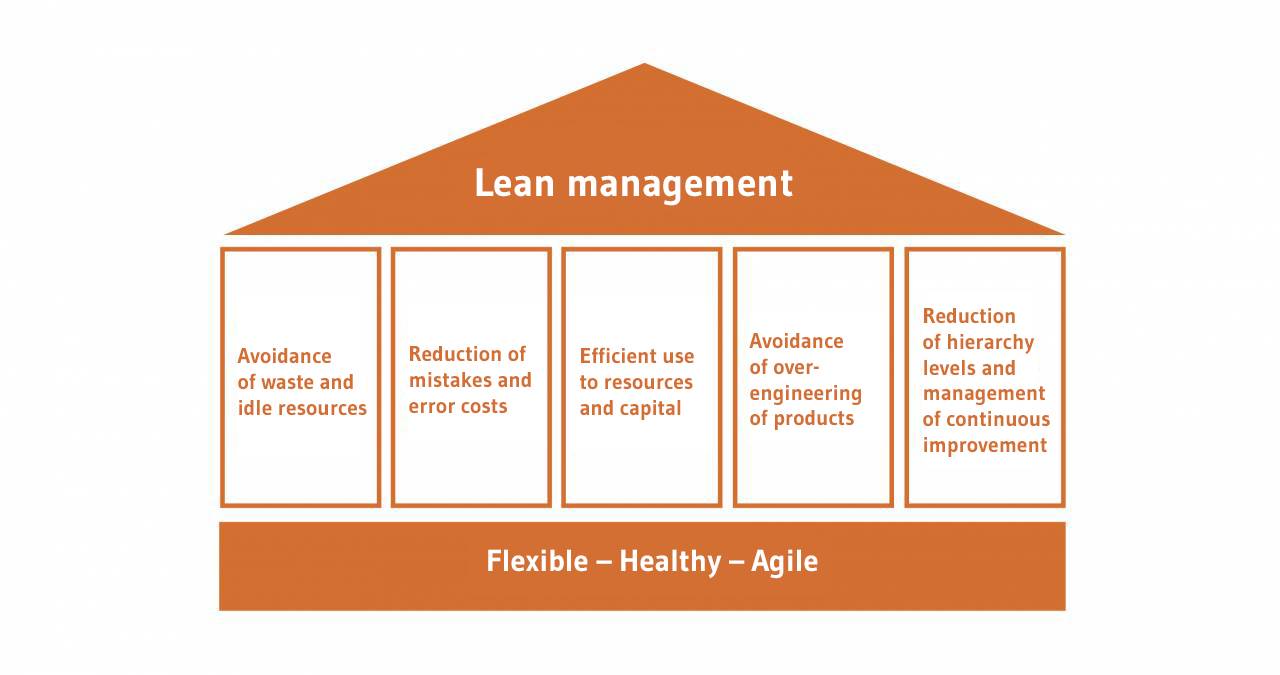

A popular version of Kaizen could be the Kaizen blitz, also called a Kaizen event. It has become an useful and customary tool in lean management. Lots of firms have incorporated it within their business culture very accurately.

The clients are now establishing a new shipyard with state-of-the-art manufacturing facilities including two 400 M long new building dry-docks create vessels upto 120,000 DWT.