The result shows how the Amezcua Bio Disc has the capacity to to convert the facet effects of plain faucet water into positive results. Water helped by the Amezcua Bio Disc has a level of your energy and relaxation. Test results also reveal anytime the Amezcua Bio Disc is held by the testers, their energy and harmony levels showed a large increase.

Among essentially the most popular maritime companies that operate typically the area, Blue Star Ferries have launched a name on their own. The company a great integral a part of the Attica Group and was founded in 92. Since then, the company has provided excellent ferry services. As a result the excellent services and facilities how the company provides to travelers and tourists, the company has been accredited several of one of the most prestigious awards and accreditation. Certification of ISO consultant 9001 has additionally been accredited to business. The ferries from the company are upgraded from time to time, that travelers obtain the best the them. In case, problem of a ferry isn’t good, this replaced any modern and the new boat.

If you add noise to the audience in way of a rule breaker, the c’s will soon stop adhering to the policies. And also of course – people that not consider the rules is more probably to put up for sale company secrets, impose threats to the machines and be an overall liability.

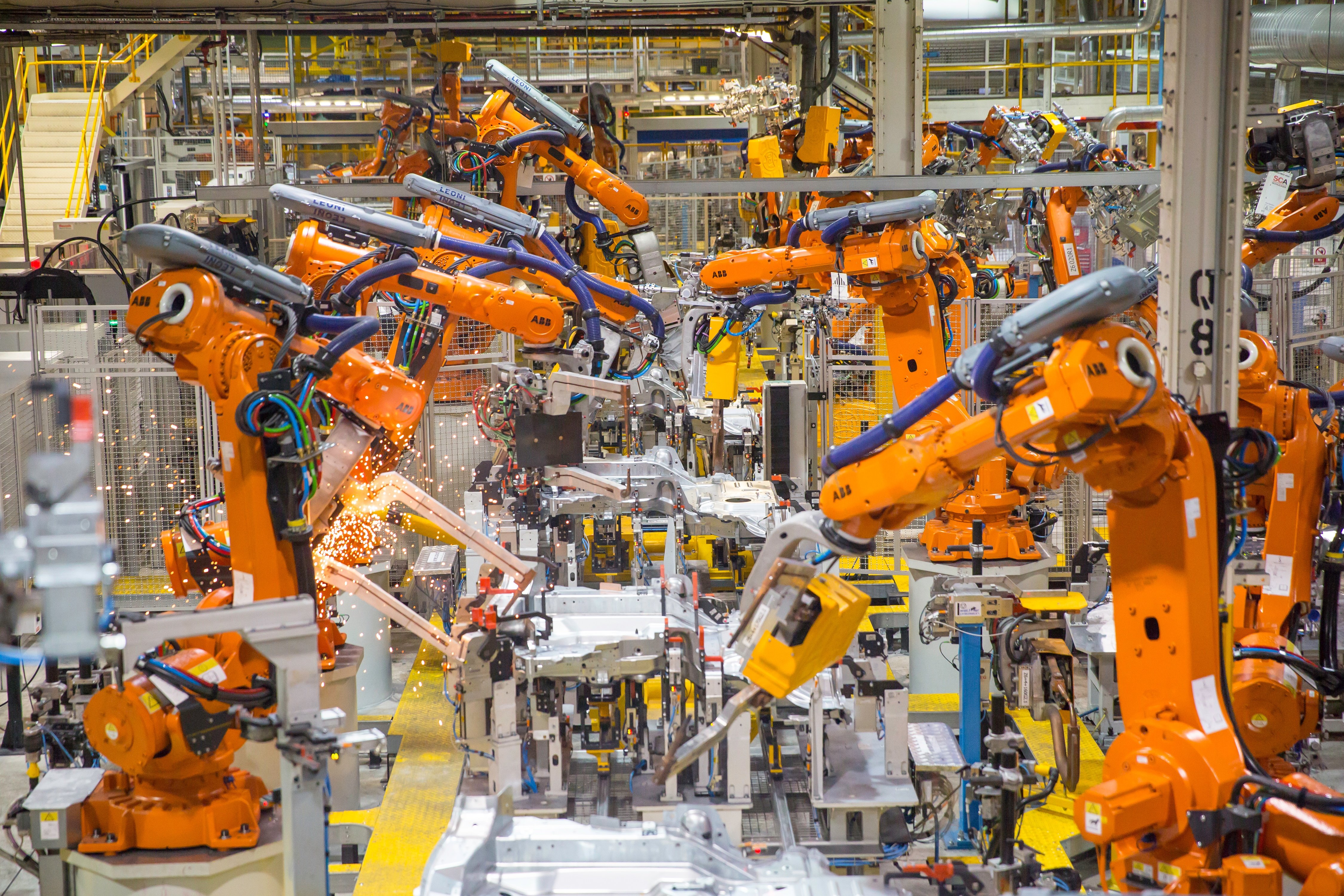

Don’t dismiss Toyota. Individuals who say that Toyota has messed up because of lean aren’t clear about Toyota’s history or sluggish it is . root involving their struggles. Toyota has a great supply chain as well as modification and best, long-term implementation of lean manufacturing. In fact, the ISO consultant how the company started develop the actual 1950s could be the original blueprint for lean manufacturing. Authentic root associated with their problems: the change of strategy in the 1990s turn into the largest automotive manufacturer in exciting world of. Bottom line, they tried to cultivate too now!

There are several people which do more work can compare to others. In comparison these using more power to help which less ability, so that the lean management system would accomplish the task. In order to do this you need your together with teamwork mind.

Pay awareness of the data. Many lean implementations are done sub-optimally. Believe look good because from the emphasis relating to the visible. People pay care about establishing visual controls, fool-proofing assembly lines, laying out factory floors and “walking the Gemba” – and can are superior. You have to do those techniques. But that’s only half the task.