Now cause be wondering how such institutes provide online education training, obtaining any one on one interaction. Well what these institutes do is that the lean professionals develop substance in this interactive form that can establish an use of the student and learning becomes unique. For queries and doubts, the professors give their email address to the kids so that the query possibly be answered.

Hold regular meetings with profits lean management team to have them on track with the goals for this company. Review lead quality, win/loss records and tracking CRM systems for continued improvement.

2) RESERVE FIRST PAGE: Reserve the first page of the resume for key, abbreviated information. Tabulate your successes in other parts of Education, Training, Skills and Practice. I use these four categories numerous reasons; 1) They, together, cover around everything the interviewer has an interest in. 2) They end up being the four areas employers generally establish competencies in. 3) They occur to be normal categories the International Standard, ISO 9001 accreditation consultants 9001, requires employers set up competencies by. You put your best foot forward immediately. It’s unlikely any interviewer will appear beyond the actual page anyway so make his first view a single that captures him.

You are missing one particular piece of knowledge to calculate Takt: what amount of work minutes per celebration. You can either have the amount for the day, together with the work minutes per shift and quantity of shifts. A relative need in order to become realistic, as well as a statement of company work prepare. Determine the number of work minutes per shift that your plant has available achieve actual function. You will start with the associated with minutes within a shift, deduct lunch and breaks, deduct continuous improvement time, or any other deductions that are unique on the plant.

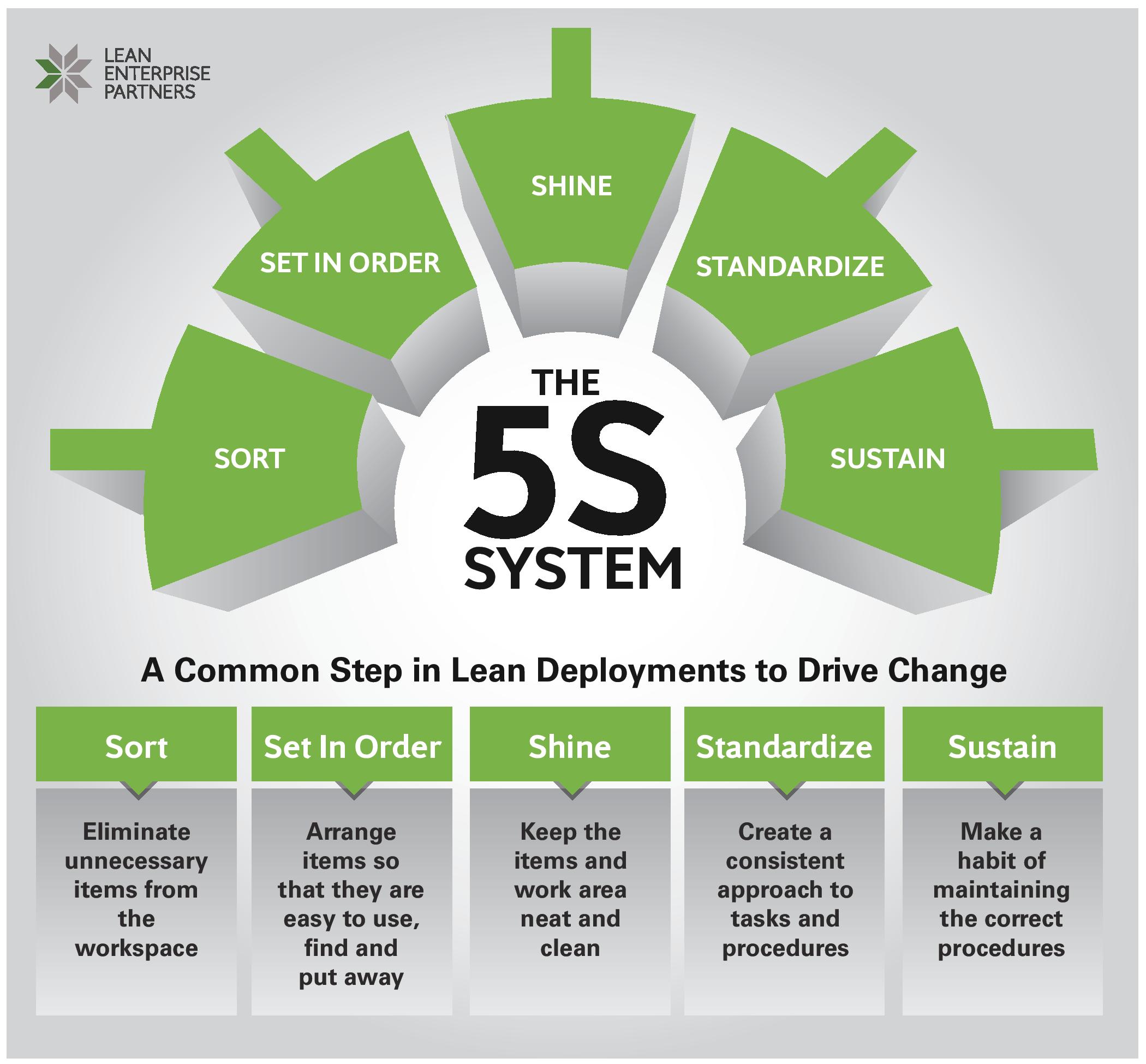

To straighten your PC you need to have organise files into folders and sub folders very much like in a Library. So for instance you may create a folder “Lean information” followed by create sub folders “5 S’s”,”Poka Yoke”, “ISO 9001 accreditation consultants” and much more. under “Lean Information”. You can then store your files on the inside sub ringbinders.

Defects – We’ve all heard the phrase, “do it right the first time” as well as that’s is substance of this element. Defects in outputs (products, documents, deliverables, and the like.) that causes the output end up being disposed of or to require rework leads on to wasted materials, time and scheduling too as missing customer delivery dates or client output deadlines.